Clothing, as an indispensable barrier between the skin and the environment, is critical in regulating the wearing comfort of the human body in daily life.

By exchanging heat and moisture with the outside environment through the medium of textiles, the body-textile microclimate is formed between the clothing and the human skin. A body-textile microclimate with appropriate temperature and humidity (32 ± 1 °C, 50 ± 10% RH) provides both physical and psychological comfort for the individual, however, its equilibrium is often disrupted due to weather or human behaviors. For example, when going from a comfortable environment to a hot or cool environment, the human body is unable to quickly adapt to the transition, resulting in unpleasant heat/cold irritation and possibly even medical emergencies.

With the ongoing development of the national health system, people are gradually shifting from a negative lifestyle based on overdraft and medical treatment to a healthy lifestyle centered on healthcare and prevention. Therefore, wearable thermoregulatory clothing that can keep the body-textile microclimate in a comfortable range has been a long-sought but challenging aim for smart textiles. Active responsive textiles allow for the warming or cooling of the human body depending on the surroundings. By sensing the stimuli (e.g., temperature, humidity, light, electricity, and mechanical), clothing is able to adjust the exchange efficiency with the external environments or realize energy absorption/release. Recently, phase change materials used to regulate temperature fluctuations without additional energy have attracted widespread interest from researchers.

Fiber-based phase change textiles are mainly prepared by post-finishing, capsulation embedding, or skin-core fiber structure. Liu et al. proposed to impregnate paraffin into nonwoven, but this suffered from leakage defect. In recent years, electrospinning technology has been widely used to prepare phase change textiles for personal thermal management due to its high structural designability. Li et al prepared multifunctional films with sufficient enthalpy and the phase change capsules were strung on the fibers with a “candied haws stick” structure. However, electrospinning fibrous membranes have been plagued by low strength and poor durability for a long time. This makes it difficult for the prepared fibrous membranes to meet the requirements of daily use.

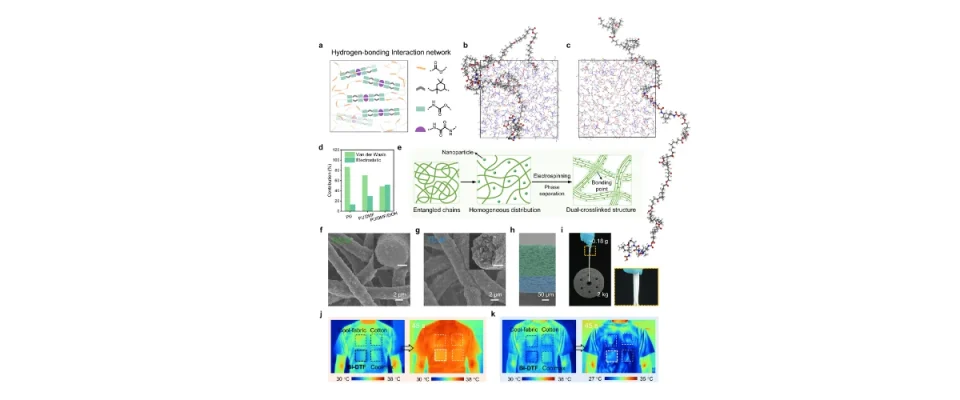

Polyurethane (PU) elastomers have attracted much attention due to their excellent mechanical properties and applicability. Structural design strategies based on various intermolecular interactions (e.g., hydrogen bonding, π-π stacking, and ionic cross-linking) have been widely explored, indicating the feasibility of electrospinning fibrous membranes with high strength and elasticity. It is worth noting that the strong entanglement of polymer networks makes it difficult to develop electrospun fibrous membranes with ordered molecular chains and satisfactory mechanical properties. In addition, it remains another challenge to improve the particle loading and homogeneity of membranes to ensure their reliability in functional applications.

Herein, we conceive a hierarchical structural engineering strategy by combining the hydrogen-bonding interaction network and physical bonding sites to fabricate the toughness composite fibrous membrane with efficient resistance to external forces. The PU polymer with high hydrogen-bonding content was constructed and through molecular dynamics (MD) simulations, we found that aggregation of molecular chains can be reduced by adding ethanol (EtOH), which leads to easier molecular movement and orientation.

In particular, we combine this strategy with the electrospinning technique to shape functional nanoparticles into PU matrix. The nanoparticles were distributed in the interconnected fibers and showed their high binding stability. Moreover, the bi-directional thermoregulation fabric (Bi-DTF) was assembled, which could eliminate the irritation from environmental switching, extending the body’s comfort. The as-prepared Bi-DTF exhibits high strength (12.7 MPa) with superior elastic recovery, continuous workability, as well as excellent durability (500 rubbing or 50 washing cycles).

News Courtesy : Nature.